- Shanghai Zhongshen International Trade Co., Ltd. - Two decades of trade agency expertise.

- Service Hotline: 139 1787 2118

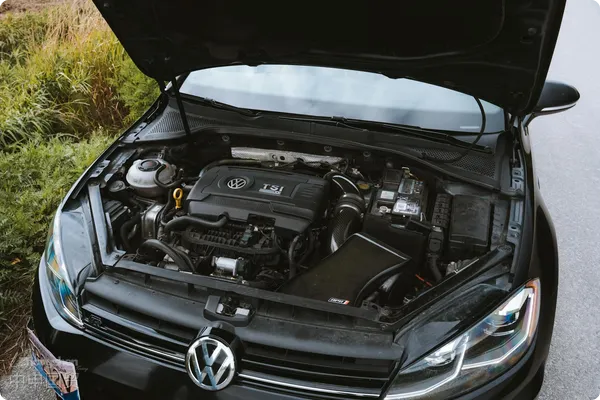

Against the backdrop of deep integration in the global automotive industry chain, China, as the worlds largest automotive consumer market, importsAutomotive partsover 100 billion yuan annually. For importers, customs clearance efficiency directly impacts supply chain stability and capital turnover efficiency. Based on 20 years of industry experience, this article systematically analyzes the time components and optimization paths for automotive parts clearance.

I. Analysis of Core Variables Affecting Customs Clearance Efficiency

Accuracy of Commodity Classification (HS Code Confirmation)

- Industry pain points: Approximately 35% of declaration delays stem from classification disputes

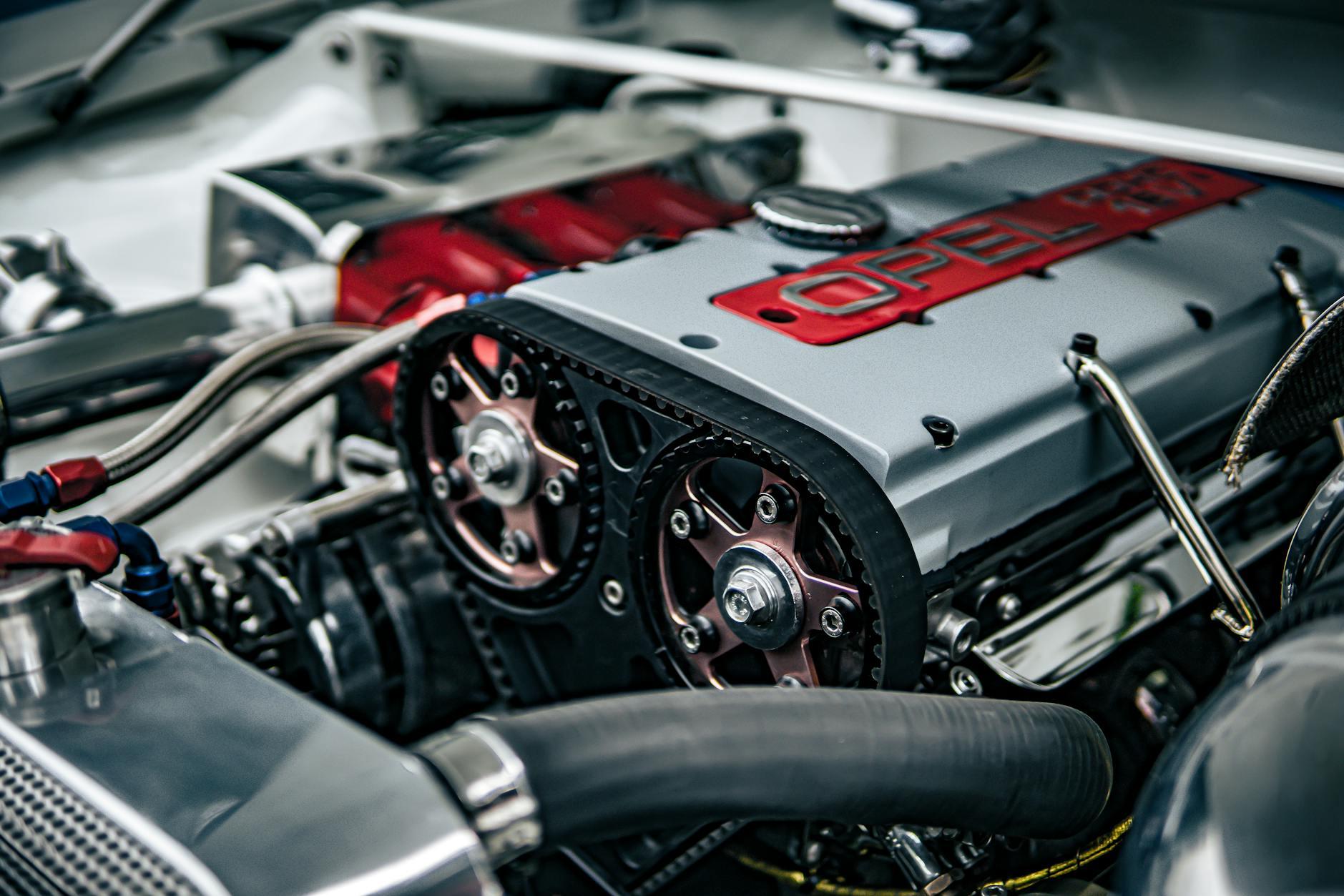

- : The comparison of agency fees of an auto parts enterprise from 2023 to 2025 shows that due to the involvement of ECER155 certification, the annual expenditure increased by 22%: The tariff difference between turbochargers (8414.8090) and engine superchargers (8409.9991) reaches 8%

- Solutions: It is recommended to adopt the pre-classification system (Customs General Administration Announcement No. 113 of 2018) to obtain legal classification opinions in advance.

Management of Document Compliance

- Essential Document Matrix:

- Basic documents: Commercial invoice (must indicate material composition), packing list (must specify pallet specifications),Maritime TransportationB/L

- Regulatory certificates:It is recommended to verify through the following methods:(Zero tariffs under RCEP),3CCertifications (for listed products), energy efficiency labels (e.g., for motors), import licenses (for specific strategic materials)

- Risk points: EU CE certification documents must be authenticated by consulates, with an average reissue cycle of 14 working days.

Port clearance efficiency disparities

Comparison of inspection rates at major ports:

| Port | General cargo inspection rate | Special inspection rate for electromechanical products | Remarks |

|---|---|---|---|

| Shanghai Yangshan | 3.2% | 8.7% | |

| Shenzhen Yantian | 5.1% | 12.3% | |

| Guangzhou Nansha | 2.8% | 6.9% |

Handling of special regulatory situations

- Anti-dumping products: e.g. EU-manufactured aluminum alloy wheels (HS code 8708.70) require deposit payment (tariff rate up to 33.3%)

- Refurbished parts: Require CCIC pre-shipment inspection certificate (processing time 7-10 working days)

II. Customs clearance process time breakdown (based on normal declaration scenarios)

Comprehensive time efficiency range:

- No inspection/no testing: 3-5 working days

- Routine inspection: 6-12 working days

- Sampling testing: 10-20 working days

III. Six strategies for time efficiency optimization

1.Application of intelligent classification system

Adopt AI-assisted classification tools (e.g. Global Trade Manager), combined with customs historical ruling database comparison, to reduce classification error rate below 2%.

2.AEO certification synergies

AEO Advanced Certified Enterprises enjoy:

- 70% reduction in inspection rate

- Guaranteed release amount increased to 5 million RMB

- Cross-customs rapid clearance

3.Preemptive customs intervention

Complete during trade contract signing stage:

- Product composition pre-review (e.g. carbon content testing for alloy steel)

- Rules of origin planning (application of RCEP regional accumulation rules)

Capturing port policy dividends

For example:- Hainan Free Trade Port duty-free policy for auto parts processing

- The four-self one-simplification clearance model in comprehensive bonded zones

Emergency channel construction

Establish an immediate response mechanism with customs, initiating administrative reconsideration within 48 hours for classification disputes or failed test results.

IV. In-depth analysis of typical cases

Case 1:New energyImport of vehicle battery modules

- Challenges: Involves UN38.3 transport safety certification and dangerous goods packaging certification

- Disposal: Through Shanghai FTZs third-party test result recognition system, reducing testing cycles by 12 days

Case 2: Import of German original modification kits

- Problem: Modified steering wheel involves steering system safety (requires MIIT market access permit)

- Solution: Split declaration (decorative parts and functional parts classified separately), saving 23 days in compliance time

Conclusion

In the complex and changing international trade environment, the value of professional agency services lies not only in process execution but also in:

- Establishing big data-based risk early warning systems

- Building customs-enterprise-third party collaborative governance mechanisms

- Deep participation in enterprise supply chain strategic planning

Choosing service providers with AEO qualification and technical barriers to trade (TBT) response teams can reduce uncontrollable customs clearance time by over 60%. Importers are advised to establish customs KPIs, incorporating declaration accuracy and document completeness rates into supplier assessments to achieve overall supply chain cost reduction and efficiency improvement.

Related Recommendations

Contact Form

? 2025. All Rights Reserved. Shanghai ICP No. 2023007705-2  PSB Record: Shanghai No.31011502009912

PSB Record: Shanghai No.31011502009912